| |

|

|

|

|

|

|

|

|

|

The team |

|

Equipements |

|

Man-lifting Kite |

|

Home |

| |

| After our discovery that the kite Saconney used for human ascension (web page "Team"), we decided to do the same by making kites and building the winch. |

| |

| Kite Saconney |

| |

| We started in 1994, by making a kite with cells of 1.20m and 25kg, very difficult to handle and quite unmanageable. We decided to return to more reasonable dimensions. |

| |

|

|

|

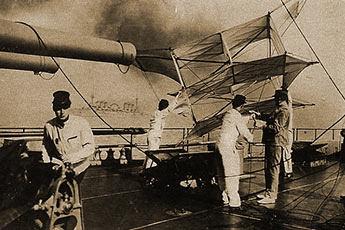

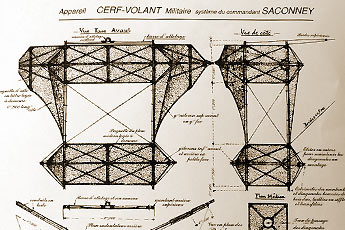

I got a plan thanks to Jack, and in this plan kites have cells of 1m. These are those who were on board the Edgar Quinet. (picture on left)

We are now working with cells of 1 m, 5m wingspan of 3.80m in depth, a total area of 13m2.

We looked at how to do a reasonable price: the bamboo, I found it in garden centre. The canvas, in a discount store, a full roll which had suffered smoke from a fire but only the first two layers were blackened.

This fabric is a cotton / polyester mixing, but does not distort the frame or on the bias, really ideal for making these kites. |

|

| |

| Nicole is an expert seamstress Saconney: "I have an old sewing machine family (Singer), purchased used and installed in a professional shop table, recovered and adjusted to fit the machine. At first I stitched with polyester thread, because the cotton breaks too easily and deteriorates. Now I have a thread that does not break, and when the seam is made, it does not move. |

| |

|

|

|

The thread is not slipping, there is friction. I sew in "zigzag 3 points" only for safety, because if the wire had possibly break the seam does not fall apart, unlike a "zigzag" classic.

At the beginning I had an old sewing machine with pedals that can only do the straight stitch, but from the moment we started the construction of more elaborate kites whose Saconneys we bought an electric machine.

Initially there were rubber pads, as they worked hard the spinnaker, it's easier, it drives better. And finally I kept it there for Saconney system and it works very well."

|

|

| |

| For sewing it takes 52 hours more thirty hours for wooden frame and shroud. Installation and settings take a little morning. |

| In all it takes about 85 hours a kite.

On each Saconney there is a logo that is one of the representations of the Man-Bird of Easter Island.

The magical rite of Man-Bird has continued until 1866 on Easter Island.

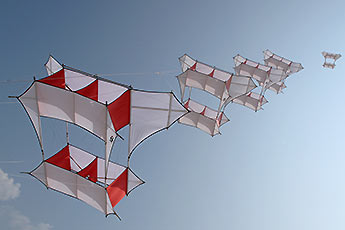

So we started to make the train of lifting, first one first, then second, third and so on. The train of lifting (6 kites) was builded over ten years, and now there are two kites in manufacture. |

|

|

The first kite, it was tested, of course, the followings are a copy of the first and therefore does not require different settings, there are only small details of settings.

Bamboos

The frame is made of bamboo section 25/30. The bamboo we buy are 4.20m long. The Saconney folded fit in pockets of 3.80 x 0.20 m.

|

| |

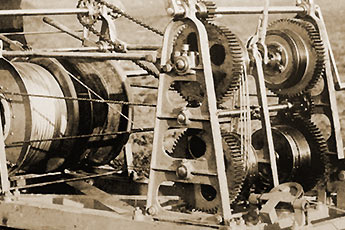

I had a first winch, but that has nothing to do with the one I use today. It was made from a boat windlass manual (*) that I bought at the store “"les puces de mer" at La Rochelle. (picture of the first winch below)

(*): The windlass is a winch horizontal axis used on ships to raise the anchor. It is also used to transfer the hawsers (large rope).

We copied an original model of winch developed by Saconney. But we have kept only a half.

At the time, they had two winding systems: one for holding the main gear and the other to to bring back the nacelle. Sometimes releasing the kites traction of the nacelle, it was not sufficient for it to back down so they had a second cable was thinner to bring the nacelle to the ground. (picture below, in the center)

The winch was made with recycled materials, spare of motorized cultivator. Some parts were made of cast iron. The motor rotates twice as slow in reverse, without changing the engine speed.

When we clutch, the rope unwinds to raise the kite. If we have a motor problem or if the belt breaks, we can bring the kite with a crank gear.

(picture of the current winch below, at left an right)

|

|

| |

| The cable |

| |

| We have 300m of cable, for the reserve between the winch, mooring foot and the first kite, more climbing, this is the minimum we could have. |

| |

|

|

We choosed the halyard pre-stretched polyester, with a diameter 8, resistance 2 tons. This one is the halyard for raise, which is red and white, because we could not use steel cable festivals. Thus, the machinery to bring a steel cable on the winch is different from that one used for a polyester cord, which can be hoisted on a winch or a windlass boat.

The steel cable deforms very quickly and we must be able to store it and not twist it because it may deteriorate rapidly. We also have a rope diameter 9 (blue and white) to raise people with kite. The rope used to keep the foot of the person who ascends has a diameter of 14, such as that used to fix the kites on the main halyard. (photo on left) |

| |

| The nacelle |

| We will design a new nacelle system. I made plans and templates for cutting and assembly. By cons I gave up some things, like the attachment on the main cable system as too complex and with a risk of tangling. I did a test but it was unmanageable, because the pulley never stays in the cable |

| |

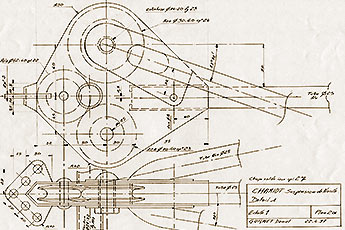

| When you pull on it is always a risk of twisting and the system does not rest aligned. I drew the suspension system of the pod on the main cable (see his plan below) with the kind Saconney braking system, and removable nacelle for it to be transported. It will be in tubular frame with a solid background, ring stiffness over the mesh to prevent someone from falling out of the nacelle. |

| |

|

|

|

We also asked for a quote to make a wicker nacelle 70cm squared.

Two new kites being manufactured by Nicole, should be used to raise the new nacelle.

They are identical in size to those already built. There is only the color changes, they will be green on the sides instead of red. The color green is just a matter of fabric available.

For cons, the red color was a strategic choice to be visible from the side, because white can get lost in the sky. |

|

| |

| We bought the red fabric by thinking that the color would be ok on a long time, but ultimately the color held only ten years. Sand, rain, sun, moon ... were winners and now the material has lost its colour. For example, during the Festival of Berck they are mounted 24/24 for 10 days. Some mornings the canvas is a bit relaxed, then a voltage setting on again. With 3 and a half hours of assembly, and for both disassemble and store, it would not be possible to do every day. |

| |

| |

|

|

|

|

|

|

|

|

|

The team |

|

Equipements |

|

Man-lifting Kite |

|

Home |

|